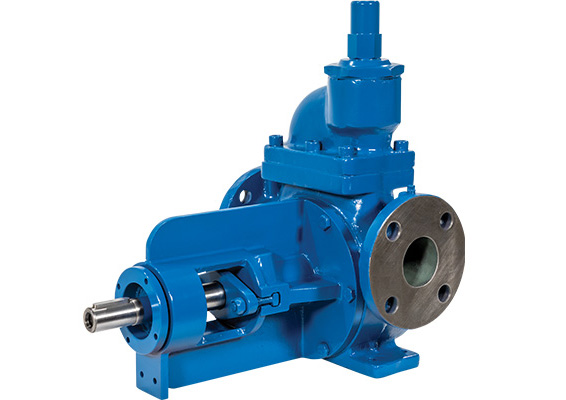

The Shanley Rotary Piston Pump has an exceptionally unique "rotary-piston" design which is based on the fundamentals of piston pumps. A piston pump is the most efficient and best performing positive displacement pump.

The “rotary piston” design however, completely eliminates the requirement of inlet and outlet valves and has large openings. When the rotor is turned, a reciprocating action is caused so that the shuttle and piston work like two double acting pistons in their respective cylinders, resulting in four large successive flow deliveries per pump revolution.

The rotary piston pump runs at higher speeds as compared gear and vane pumps due to much lower suction pressure requirements. Rotary piston pumps can handle higher viscosities than gear and vane pumps and provide gentle non-emulsifying, non-shearing handling of the fluid pumped. Materials of construction are cast iron, steel or bronze. The Shanley Rotary Piston Pumps are supplied with full flow, built on relief valves. Shaft seals with packing, mechanical seals or cartridge mechanical seals. Optional Steam jackets for pump heating.

Pumping Applications

Shanley Rotary Piston Pumping applications include loading and unloading of tanks, tank trucks and tanker rail cars due to their ability to completely empty both suction and discharge piping. Typical transfer, circulation and process pumping of a very wide range of fluids from thin fluids to extremely viscous fluids without any pump modifications.

Pump Construction

Shanley Rotary Piston Pumps are made in a variety of materials like cast iron, steel, and bronze for corrosion resistance. Shaft sealing is normally gland packing bur a variety of mechanical seals can also be provided. Pumps are also available with heating or cooling jackets which can also be retrofitted on existing installations.

Pump Drive Types

Rotary piston pumps can be direct driven with motors, motors through gear reducers or any direct drive. The robust bearing design is also well suited for V-belts drives or chain drives with no additional bearing supports required.

Typical Liquids Pumped

Asphalt, bitumen, caustic soda, chocolate, coconut oil, cooking oil, corn oil, crude oil, detergents, diesel fuel, enamel, epoxy, ethylene glycol, fats, fatty acid, fish oil, fuel oils, gelatin, glucose, glycerin, grease, honey, ink, latex, molasses, oil, paint, polymer, resins, soaps, soybean oil, starch, styrene, sugar syrup, tar, transformer oil, turpentine, varnish, vegetable oil, viscose, wax.

Rotary Piston Pump Features

The following are some of the outstanding features of the Shanley Rotary Piston Pumps that makes them better suited than gear pumps for many pumping applications:

- Shanley Rotary Piston Pumps can pump high viscosity liquids with much greater ease and much lower suction required, even at higher rotating speeds. Liquid easily flows into and out of the 4 large pump cavities without restrictions. Gear and Vane pumps have many more gear teeth or small pockets to be filled and require higher suction pressures.

- The liquid is not sheared, agitated, heated or emulsified as with gear pumps, protecting sensitive liquids like chocolate from any potential damage.

- Ideal for truck loading and unloading pumping applications and will completely empty the pump suction pipe and discharge pipe and run dry without pump damage. Gear and vane pumps will be damaged if run dry.

- Ideal for asphalt pumping applications and can be used in high temperature pumping conditions, up to 300°C, 530°F.

- A longer, single pump shaft that is supported with 2 rugged bearings, spread wide apart, taking care of any potential external radial forces from the pump driver. The pump can be driven by a motor, truck mounted PTO, V-belts or a chain drive with very reliable and long service life.

- Supplied with full flow, built-on pressure relief valves for protection in the event of a closed discharge valve or upset condition, protecting the pump and motor from damage due to overpressure.

- Due to large surface areas, the potential wear from abrasive fluids is spread out and hence dramatically extends the pump life as compared to the small tips of gear and vane pumps which can be subject to potentially rapid wear and shorter service life.

- External gear pumps have 2 shafts and 4 bearings which are either internally located and product lubricated and subject to wear from fuel oils and contaminated fluids resulting in shortened bearing life or externally located and thus requiring 4 shaft seals. When the bearings fail in external gear pumps the shaft center distance changes resulting in gear wear, loss of capacity and premature pump failure. This problem is solved with the single shaft design of the Shanley Rotary Piston Pump.

- All Shanley Rotary Piston Pumps are uniquely supplied with a clearance position device as a standard feature. This clearance adjustment allows for wear compensation even after many years in service. This unique feature extends the pump life.

- Shanley Rotary Piston Pumps are inherently quiet. Gear pumps are noisy.

- Due to higher volumetric and mechanical efficiencies the power requirement is lower, resulting in energy savings, lower running costs and smaller motors required as compared to gear and vane pumps.

- Simple, back pullout design and adjustment device for wear compensation make it a simple and easy pump to maintain without removing from the piping and base plate.

Close Menu

Close Menu