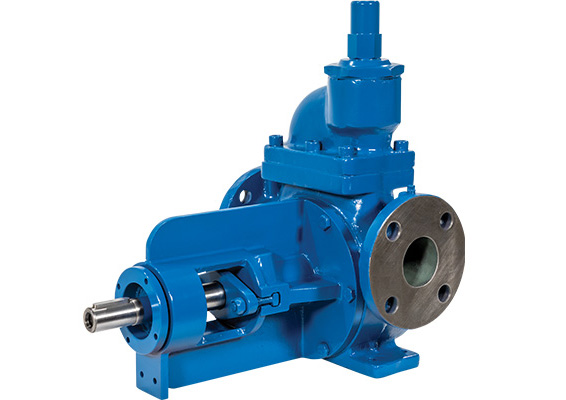

The Shanley SEP Progressive Cavity Pump is an extremely versatile positive displacement pump with a non-pulsating flow that can be used in many different pumping applications. The SEP pump is specially designed for abrasion resistance in tough pumping applications and can pump up to 60% solids. The SEP pump is also ideal for liquids with higher viscosities, or thickness, than water. The gentle pumping action of the SEP pump makes it great for pumping sheer sensitive fluids. The SEP pump is also used for pumping fluids with varying viscosities, for pumping against varying discharge pressures and for pumping applications requiring varying flows using a speed controller. Most commonly used for sludge and polymer at sewage treatment plants, feeding filters and filter presses, centrifuges, feeding oil water separation equipment, food pumping applications like honey, juice concentrate, grapes in wineries, crude oil, viscous chemicals, bilges on ships, coal water slurries and much more.

SEP Features

- 9 pump sizes immediately available from our inventory in cast iron and stainless steel

- Shaft packing or mechanical shaft seals available, all standard with shaft wear sleeves

- Flows up to 750 GPM, Discharge Pressures up to 350 PSI, Suction lift up to 28 feet

- Fluid viscosities to 300,000 Centistokes, Temperatures to 302 degrees Fahrenheit

- Cast Iron pumps have suction clean out/inspection ports

- Lubricated and sealed universal joints for long life

SEP Design

The Shanley SEP Pump is a progressive cavity pump in 1 and 2 stage design. It’s resilient and tested design is optimal for demanding pumping applications. It’s ruggedized universal joints with wear bushings are sealed and lubricated from the pumped liquid to provide long service life. The SEP pump is available with equal wall stators for lower starting torque and higher discharge pressures.

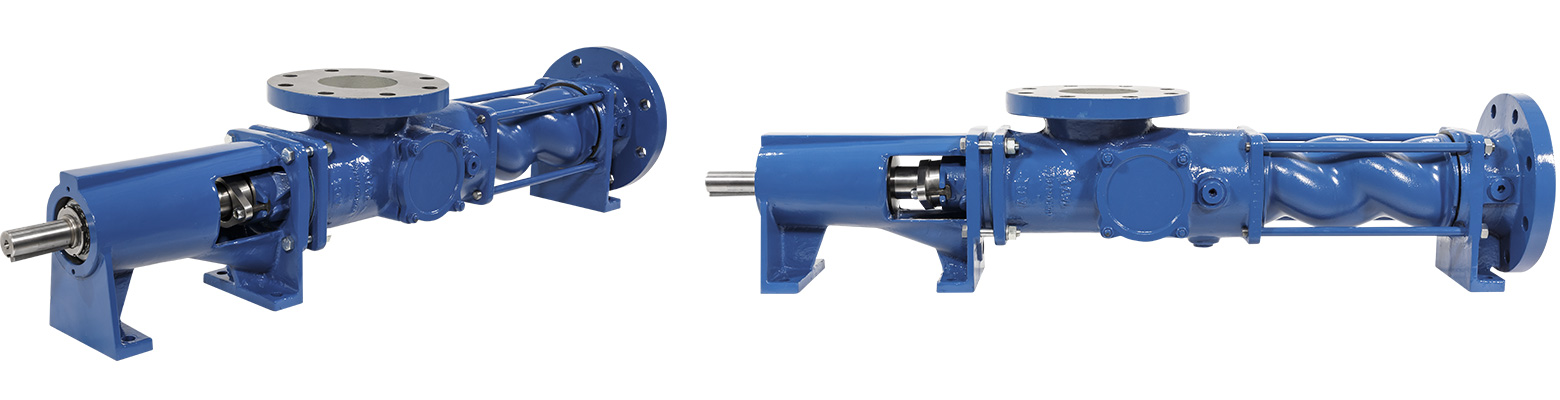

Pivot Joint Design

The SEP Series pivot joint offers unique advantages while simple in design.

At both ends of the coupling rod, which connects the rotor and drive shaft, are heavy duty pivot points. Each pivot joint consists of coupling rod bushings (inside conical), two yoke bushings and a coupling rod pin. All of these parts are made of hardened steel. A retaining sleeve prevents radial movement of the assembly.

The complete pivot joint assemblies are encapsulated with oil, and sealed by means of an elastomeric cover sleeve which fits into labyrinths at each end of the assembly, and fixed in position by “band-it”® bands.

SEP Pump Video

SEP Series Pump Performance

US

Metric

SEP Curves

SEP Drawings

Shanley SEP Series Screw Pump Parts

We stock an entire inventory of replacement parts and upgrades for the SEP line of pumps and pump products. From seals and screws to entirely rebuilt systems.

If you are looking to repair your current pump system or even rebuild your current one, contact us today and ask for one of our factory trained engineers at 847-439-9200.

SEP Pump Industries & Applications

Applications

- Transfer Service Sampling

- Polymer

Feed

- Chemical

Feed

- Dewatering Sludge Transfer

Fluids

- Effluent with & without solids

- Slurry Media

- General

Sewage

- Protective

Chemicals

- Milk of

Lime

Applications

- Centrifuge

Charging

- Kiln

Charging

- Pit

Emptying

- Transfer Filter

Charging

- Drainage

Metering

- Gas

Scrubbers

- Tank Loading

/ Unloading

- Cellulose

Fluids

- Acids

- Adhesives

- Caustic Soda

- Grout

- Cement Slurry

- Dye Liquor

- Dye Baths

- Flouring Plaster

- Lime Slurry

- Ink

- Lyes

- Motar

- Coal Slurry

Applications

- Process

Transfer

- Loading /

Unloading Metering

- Collecting

Fluids

- Acids

- Adhesives

- Colors

- Cosmetics

- Detergents

- Glue

- Lacquers

- Hair Oil

- Hand Washing

- Cream

- Paints

- Shampoos

- Waxes

Applications

- Process Transfer

- Loading /

Unloading Metering

- Collecting

Fluids

- Alcoholic Beverages

- Apple Puree

- Baby Food

- Beer

- Beet Sludge

- Biscuit Dough

- Citrus Fruit Masher

- Cream Cheese

- Edible Oil

- Eggs, Raw

- Fats

- Fish Residues

- Fruit & Berry Masher

- Honey

- Ice Cream

- Lard

- Meat Extract

- Milk

- Mustard

- Tomato Paste

- Vegetable Oil

- Wine

- Yeast

Applications

- Transfer

- Loading /

Unloading

- Collecting

Fluids

- Crude Oil

- Oil Sludge

- Oil Tank Residues

- Processed

Oil

- Waste

Products

Applications

- Transfer

- Loading /

Unloading

Fluids

- Fuel

- Oil

- Coal/Oil

Slurry

- Coal/Water

Slurry

Close Menu

Close Menu